Where? Many

European countries such as France, Denmark, Germany, Italy etc.

When? 1400’s

My Version:

I have since updated this paternoster to red silk tassels and replaced two white beads with another two white beads without impurities and a more uniform shape.

Images of various pieces:

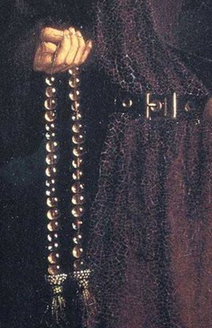

Figure 3- Lochner, Stefan - Outside of an Altar Wing - 1445-1450

Figure 4- Martyrium der Hl. Ursula 1448

Materials and

techniques:

-Glass (glass beads)

-Technique: lampwork

techniques to recreate a similar shape and size in each bead.

String: Corded strings with tassels can be seen in most of the art.

Details of the Recreation:

I chose to recreate the number of glass beads that can be seen on a number of the images that I have collected. The beads are simple, in one or two standard colors. They are unadorned, keeping the piety of decoration that was common at the time.

Working with Glass:

I have been working on

developing my skill at melting glass and shaping it over the last couple of years.

I have learnt a lot, including where in the flame certain glass must be placed

so that it doesn’t ruin the colour or texture. I have learnt how to steadily

place my hands and rotate both glass and mandrel so that an even amount of

glass, at the right temperature, is kept at the right heat to reproduce the

desired bead.

The necklace presented a

variety of challenges. Glass is a dangerous, sometimes fickle substance, and

certain colours only work properly at a certain heat.

Some of the trickier

techniques (and melting glass onto a mandrel and keeping it even is tricky to

start with!) that I used for this project include:

·

Studying each (photo of) bead in a variety of lights to get

an accurate grasp of the details.

·

Working with tricky colours.

·

Combining colours and the perfect melt down spot to get a

more accurate shade and shape.

· Shaping similar size beads

Details of the equipment and resources:

·

I used a graphite paddle, mandrels, bead release, a knife, fire

annealing and gravity. I try to use the least tools possible and authentic

equipment that would have been used by the glassmakers of the time. Apart from

my fire set-up, all the equipment I have used would have been used at the time

as well.

·

Clear broken glass was often used as well as imported blocks of coloured

glass. (Regia Anglorum)

·

The glass rods I used to recreate these beads were Effetre Murano – 104

COE soft glass rods. This is a close replica of the glass that would have been

used at the time.

·

Bead artisans would have created a small kiln or furnace. The broken

recycled glass would be put into the furnace through holes in the side to melt

in a dish inside the furnace. Air was pumped into the furnace to keep the

charcoal hot. (Guido)

·

I use a hot head torch and MAPP gas. In the future I have plans to

recreate a small portable kiln but melting glass in a small kiln is very

difficult as getting the heat hot enough to melt the glass is a struggle.

·

Metal rods (mandrels) were dipped with a clay mixture called bead

release. The molten glass is wound onto the rod until the desired shape was

achieved. Once the bead size and shape were achieved, a design could be added

by heating thin bits of glass and wrapping them around the bead, with a

“stringer” that was heated and laid on top. (Guido)

·

I use mandrels that would have been very similar to those used, however,

mine are shorter as they don’t need to be as long to reach into a hot fire. The

bead release I use has the crucial ingredients of water, kaolin and alumina

hydrate, which is a composition that would have been used.

·

Beads would then be moved to an annealing dish in the furnace. This

would prevent thermal shock, lowering the chances of the bead cracking.

·

Instead of annealing them in a furnace, I use a product called

vermiculite to allow the beads to cool down slowly. I also use a kiln. In the

future, I would like to try annealing them in a furnace to see what it is like.

·

After the beads are finished, I remove them from the mandrels, clean

them out with some bead cleaning tools and give them a quick clean with some

soapy water.

· I included a selection of creative beads using the resources that would have been available to make this necklace. As you can see, the original colour layout is more striking in colour.

Future Projects:

·

In the future, I would like to continue to practice more difficult

skills, e.g., fine line work, millefiori use and making the Chinese Warring

state Beads which had over 100 steps each.

·

I am enjoying creating pieces from different times and cultures and I

will continue to develop my skills by continuing to choose challenging

projects.

·

I also enjoyed working with the museum and the professor when I

recreated a 133 bead Phoenician necklace, and I would like to continue working

with people like this. Not only was it very educational and rewarding, but it

resulted in me contributing to the historical accuracy of the museum- which I

thought was cool!

·

I also intend to work on another historical recreation of a glass making

set up.

Secondary Resources:

Guido, Margaret. The Glass Beads of Anglo-Saxon England: c. AD 400-700, Boydell Press,

1999.

Holgate, Barbara. “The Pagan Lady of Peel”, St. Patrick’s Isle Archaeological

Trust, 1987.

Regia Anglorum: https://regia.org/

No comments:

Post a Comment